|

|

[Home] - [News] |

Machine learning method used for the prediction of material properties

Date: 21-07-2017 Print

In the last decade, machine learning has provided us with numerous conveniences for our everyday lives. New things like intelligent web search, speech recognition, autopilot automobile are becoming more and more common. In 2016, Alpha Go's performance shocked the world with its potential not only in just a game, but also in various fields. In the field of scientific research, the idea of Big Data is changing the way researchers deal with the unknown world. In 2011, Materials Genome Initiative (MGI) was proposed by US government to promote the speed of material development. In China, the project "MGI research platform" is now under construction in Huairou science city. Nowadays, the method that combines high-throughput experiment, high-performance computing and deep data analysis is becoming more and more popular.

In the research field of amorphous alloys, the prediction of the glass-forming ability (GFA) by varying the composition of alloys remains a challenging problem for glass physics, as well as a problem for industry, with enormous financial ramifications. In the past, the discoveries of new alloy systems are mainly based on the empirical principles. Because these principles lack accuracy and universality, the development of new amorphous alloys has not been satisfying. It has been a challenging problem how to accelerate the development of new materials.

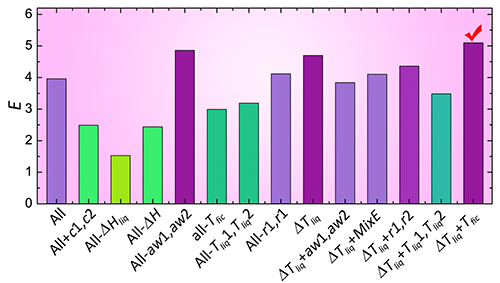

Recently, Yi-Tao Sun in Prof. Wei-Hua Wang’s group from the Institute of Physics, Chinese Academy of Sciences, collaborated with Prof. Mao-Zhi Li from Renmin University of China, and analyzed the GFA of binary alloys via machine learning. A link between alloy composition and property is established and prediction can be made accordingly. Support Vector Machine (SVM) is used to construct a multi-dimensional space and data are categorized by dividing the space into different sub-spaces. This way the correlation between input parameters and material properties is established (Fig.1). By changing input parameters, the effect of different material properties on the GFA can be assessed (Fig.2). It was found that parameter ΔTliq is most relevant to the GFA of an alloy, and the best model is developed using two parameters: ΔTliq and ΔTfic. Test on the best model showed that there is a strong correlation between model prediction and the known good glass formers (Fig.3). Such model predictions has the potential to largely accelerate the discovery of new alloys with good GFA (Fig.4). This work is a typical attempt of using new methods to solve classic problems. A more abundant database should significantly improve the performance of machine learning for much better prediction of GFA of alloys. The improvement in our ways of dealing with data has the potential to boost material research speed fundamentally.

This study entitled "Machine Learning Approach for Prediction and Understanding of Glass-Forming Ability" was published on the Journal of Physical Chemistry Letters. The study was supported by the National Science Foundation, the Ministry of Science and Technology of China, the Chinese Academy of Sciences.

|

| Fig.1 Overall setup for SVM modeling, including four major processes: building of the dataset, the learning process, model evaluation, and model prediction. (Image by Institute of Physics) |

|

| Fig.2 Input parameters’ assessment. (Image by Institute of Physics) |

|

| Fig.3 Predictions from the best SVM model. (Image by Institute of Physics) |

|

| Fig.4 Word cloud depiction of the best glass formers from SVM model prediction. (Image by Institute of Physics) |

Contact:

Institute of Physics

Wang Weihua

Email: whw@iphy.ac.cn

Key word:

Machine learning; glass forming ability; material research;

Abstract:

By applying the support vector classification method, models were developed for predicting the GFA of binary metallic alloys from random compositions. The effect of different input descriptors on GFA were evaluated, and the best prediction model was selected, which shows that the information related to liquidus temperatures plays a key role in the GFA of alloys.